-

E-mail:[email protected]

-

Telphone:+86-574-88073028

-

FAX:+86-574-88073029

QR code on

mobile phone

Welcome to Eastkey!

Welcome to Dongke!

LED cabinet lights are becoming an increasingly popular choice for enhancing the functionality and aesthetics of home spaces such as kitchens, bathrooms, and closets. Their energy efficiency, long lifespan, and sleek designs make them a favorable lighting option. However, when installing LED cabinet lights, especially in high-moisture areas such as bathrooms or kitchens, safety becomes a crucial consideration. This article will explore the potential safety concerns associated with the installation of LED cabinet lights in such environments and provide insights on how to address these issues to ensure a safe and reliable lighting solution.

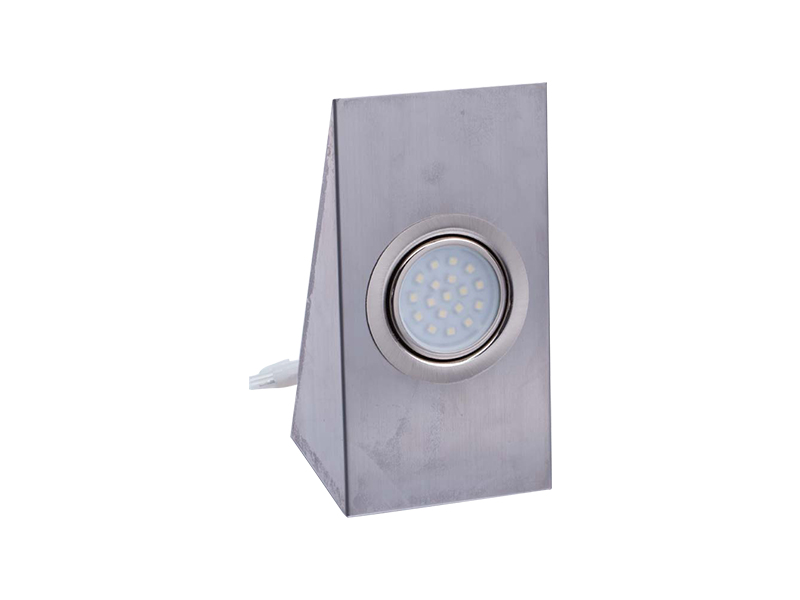

LED cabinet lights come in various designs, including under-cabinet lights, recessed lights, puck lights, and strip lights. These lights are typically used to provide additional illumination in areas where task lighting is essential, such as inside cabinets, over kitchen counters, or beneath bathroom vanities. The key advantages of LED cabinet lights include their compact size, energy efficiency, and ease of installation. However, the moisture-rich environment of certain areas can present specific challenges when it comes to their installation and operation.

Bathrooms, kitchens, and areas near sinks or water sources are subject to high levels of humidity, moisture, and even direct water exposure. This environment can be challenging for electrical components, especially when it comes to lighting fixtures. If LED cabinet lights are not properly sealed or designed for use in high-moisture areas, they may pose safety risks, including short circuits, electrical fires, and other malfunctions. The combination of moisture and electrical components can create an unsafe situation if proper precautions are not taken during installation.

One of the primary concerns when installing LED cabinet lights in high-moisture areas is ensuring that the lights are adequately protected against water and moisture ingress. The best way to determine whether a particular LED light is suitable for installation in such areas is by checking its Ingress Protection (IP) rating. IP ratings consist of two numbers: the first digit indicates protection against solids (dust, dirt), and the second digit represents protection against water. For high-moisture areas, it is essential to choose lights with an IP rating of at least IP44, which ensures protection against splashing water. Lights with an IP65 or higher rating are ideal for areas that experience direct water exposure, such as bathrooms or kitchens with frequent splashing.

The installation of LED cabinet lights in high-moisture areas must be done with careful attention to detail to avoid safety issues. First, it is important to ensure that the wiring and power source are properly insulated and protected from moisture. This can be achieved by using waterproof junction boxes, gaskets, or seals around the electrical connections. Additionally, the lights themselves should be mounted in a way that prevents them from coming into direct contact with water or excessive humidity. Following the manufacturer’s installation instructions and consulting with a licensed electrician can help mitigate installation risks and ensure that the lights function properly without posing a safety hazard.

The materials used in the construction of LED cabinet lights play a significant role in their resistance to moisture and overall safety. Lights made from rust-resistant metals, high-quality plastics, or corrosion-resistant coatings are ideal for high-moisture areas. Stainless steel and aluminum are commonly used for their durability and resistance to rust and corrosion. Plastic materials, especially when treated with moisture-resistant coatings, can also provide adequate protection against the harmful effects of moisture. It is important to verify that the materials used in the LED lights are suitable for the specific bathroom or kitchen environment where they will be installed.

Electrical considerations are vital when installing LED cabinet lights in bathrooms, kitchens, or other wet areas. Any lighting system installed near water sources must be wired according to local building codes, and care must be taken to prevent electrical hazards. For example, GFCI (Ground Fault Circuit Interrupter) outlets should be used to prevent electrical shock in the event of a short circuit or water contact. Additionally, waterproof power supplies and cables should be used to avoid the risk of electrical fires or shock. It is also recommended to install a circuit breaker or fuse for added protection. Proper grounding is essential to avoid electrical hazards, particularly in high-moisture environments.

Even with the best precautions, there may be occasional issues with LED cabinet lights in high-moisture environments. Below is a table outlining some common problems and potential solutions for LED cabinet lights installed in bathrooms or kitchens.

| Problem | Possible Cause | Solution |

|---|---|---|

| Light flickers or turns off | Moisture ingress into the electrical components | Check the IP rating and seals; ensure proper installation of waterproof components |

| Rust or corrosion on light fixtures | Exposure to high humidity or water splashes | Choose corrosion-resistant materials like stainless steel or aluminum |

| Electrical shorts or sparks | Improper installation or exposure to water | Ensure correct insulation and waterproof seals around wiring and connections |

| Light does not work after installation | Loose wiring or improper connection to power source | Double-check wiring connections and use waterproof connectors |

Proper maintenance is essential for ensuring the long-term functionality and safety of LED cabinet lights in high-moisture areas. Regularly cleaning the lights and their surroundings can help prevent moisture buildup, dirt, and debris from interfering with the light’s operation. It is important to inspect the seals and gaskets periodically to ensure they are still intact and providing adequate protection against moisture. If any signs of wear or damage are noticed, these parts should be replaced immediately to avoid potential electrical hazards. Additionally, checking the electrical connections and wiring for any signs of corrosion or wear is essential for maintaining the safety of the lighting system.

| Maintenance Task | Frequency | Purpose |

|---|---|---|

| Inspect seals and gaskets for wear | Every 3-6 months | To ensure moisture protection |

| Clean light fixtures and surrounding areas | Monthly | To prevent dirt buildup and ensure optimal performance |

| Check wiring and power connections for corrosion | Annually | To prevent electrical hazards |

| Test waterproofing and IP rating | Annually | To confirm protection against water and moisture |

top

E-mail:[email protected]

Telphone:+86-574-88073028

FAX:+86-574-88073029